As I mentioned in my previous post, my mate Andy from the newly named Prince Albert Ales has splashed out on a Grainfather brewing system. You can read my initial description of the system in this post (to save me typing it again).

The brew day started with cleaning the system, especially because it was brand new so the recommendation was to run cleaner through it for a reasonable time to remove any factory grime (I’m sure they didn’t use those exact words in the manual).

Recipe and grains were prepared in advance (today it was a German wheat beer):

Once rinsed, the Grainfather was filled with strike water and set at the target temperature to heat up:

Once at temperature in go the grains:

Then on goes a mesh to prevent the top of the grain bed being disturbed by recirculated mash liquor and later sparge water:

Then the mash recirculation pipe is fitted and the pump turned on so the mash liquor at the bottom is pumped up and onto the top of the mash:

Wait an hour and have some lunch…

At the end of the mash, there’s a foam on top of the mash:

Here’s the clever bit – lift the inner cylinder up and lock it in place so the wort can drain out of the grains into the boiler below:

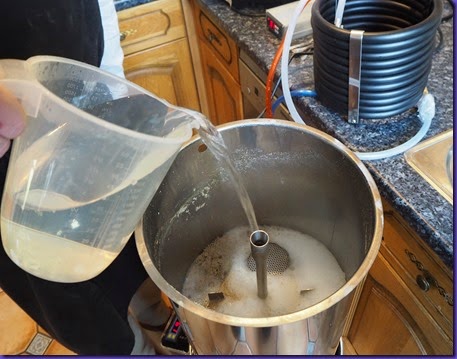

Commence sparging – simply pour the sparge water onto the top mesh above the grain bed:

Once finished, remove the mesh, and indeed the whole grains cylinder:

In go the hops and the boil commences:

At this point I left Andy to it. But at the end of the boil the counterflow wort chiller is used to recirculate the wort until chilled to the required temperature, whereupon it is pumped into the fermenting vessel.

That’s it! In all we were very impressed. There were a couple of learning points:

- The handle for the inner grain cylinder can easily come away when you are tipping the grain out of the cylinder. As a result Andy managed to drop it as he was tipping into the compost bin. Minimal damage fortunately.

- Pumping out into the FV took forever because of the hops clogging up the outlet. Looks like a hop bag is essential.

On the brighter side, the OG was 1.060 when the recipe had said 1.050, so it’s clear the system is very efficient. That’ll be the mash recirculation I guess.

Now, I just need to find £600…