On Tuesday I had my Christmas present from my wonderful wife – a day brewing at Wincle Brewery, near Macclesfield. Needless to say I had a fantastic time.

I have already posted a few general photos for my Facebook friends, but I thought I would write this blog post too. In the Facebook photos I kept them pretty general. Here I aim to be a little bit more “beery” (since it is a brewing blog after all!).

The first thing to say is that the brewery is in an idyllic location, right on the River Dane on the border between Cheshire and Staffordshire. There had been snow over the weekend, so the photographer in me was treated to some wonderful scenic opportunities.

I got there at 8.45am, and met Giles (Owner and Brewer), Justin (Head Brewer) and Hayley (Shop Manager). (Oh, and Molly the Brewery Dog, photographed above). I was immediately made very welcome and, frankly, was told that I was one of the team for the day.

The brewery has a brew capacity (“brew length”) of 15 barrels, which in metric money means the largest brew they can make is 2500 litres. They have three fermenters, plus water (liquor) tanks (hot and cold, on left of photo), mash tun (behind the blue ladder) and boiler (copper).

Malt is stored on the upper floor, and drops down a hopper into the mash tun where it is mixed with hot water. This is how my day started – “mashing in”. I was delighted to be told I could do it all, so I dashed up the ladder and opened the various values under Justin’s guidance.

The mash takes an hour, as it does in home brewing. Just enough time for a chat and bacon butties. Bloody civilised if you ask me! :-)

Sparging (washing the sugars from the grains) is a much more mechanised affair than at home. We use an old milk carton with holes punched in the bottom. In commercial breweries it’s done with a rotating pipe, so you just turn it on and leave it for an hour.

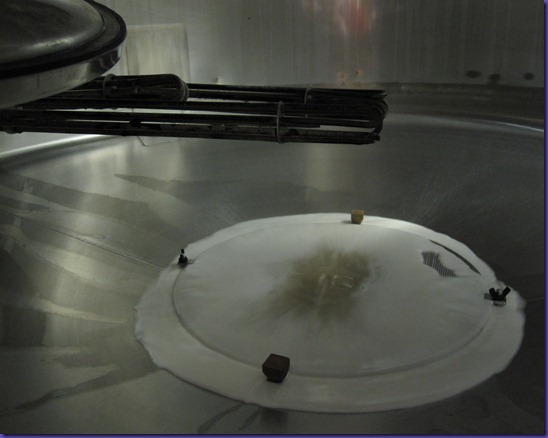

During sparging, wort is run off the bottom of the mash tun into the “underback” (see photo below) and then pumped into the boiler.

This photo is through the boiler hatch, showing the wort just starting to well up through the inlet at the bottom. The black rods above are the boiler’s heating elements.

Once the boil was underway, the mash tun had to be dug out and cleaned. (They say more than half of brewing is cleaning!). Yes, I did dig it out, but Hayley kindly went inside the mash tun to scrub it clean.

Hops were weighed out for the three additions at various stages during the boil.

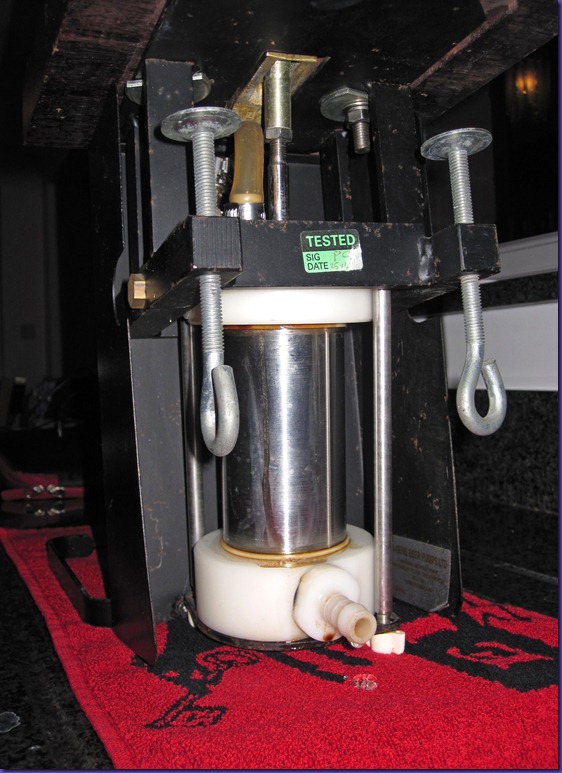

Finally, once the boil is finished the wort is pumped through a counterflow chiller (this has many plates, and allows wort to flow one way and cold water to flow the other) which drops the temperature to 20C in a few seconds. From here it goes into the fermenter. A sample is drawn off to measure the gravity…

… and also to allow the “cold break” to be assessed. This is the precipitation of proteins that occurs during the rapid chilling. As you can see, the precipitation is quite pronounced. We can’t achieve that sort of cold break at home because we use an immersion chiller (just a copper coil in the boiler, with cold water passing through it), so the chilling takes much longer (an hour or so). The more rapid the chilling, the greater the cold break.

I was very interested to see that they use dried yeast. In fact they use exactly the same strain as we use: Safale S-04. This is me re-hydrating 1kg of dried yeast.

I had to dash before the yeast was pitched, because my wife had got stuck in a snow drift coming to collect me! Giles kindly got me back up the hill out of Wincle and I headed home very happy.

If you have even the vaguest of interest in brewing and fancy a really interesting and hands-on day I’d wholeheartedly recommend that you contact Wincle Brewery. They can take groups up to about five or six. Some people go for a social event, and just like to chat, watch and of course sample the beer. Others, like me, want to get as involved as possible.

Thanks to Giles, Justin and Hayley for making me so welcome.