In my last post I wrote about moving our homebrewing to a new level with the production of a sour ale. Well since then we’ve been aiming to brew a simple English bitter for consumption at Christmas to compliment our Robust Porter and Christmas Unusual spiced ale that are currently maturing. But the pressures of work and other pre-Christmas activities means that I don’t think we will find the time. All-grain brewing is a time-consuming business – it takes us 5-6 hours on brew day.

So, on a whim, I bought a homebrew kit today! I haven’t made a beer kit since our very first brew, back in May 2010. But I thought “what the hell!”. It’d be nice to have a lighter beer in stock for the Christmas period, and anyway it’d be interesting to ferment a kit using the knowledge and equipment we have gathered over the last four years.

So I purchased a St Peter’s Golden Ale kit.

It’s dead quick and easy to put it all together, but there are a few things I did out of habit that were NOT mentioned in the very brief instructions on the box:

- Re-hydrate the yeast. It helps to get the dry yeast into liquid form before you dump it into sugary wort. Supposedly the osmotic pressure of rehydrating yeast in sugary wort can damage the yeast.

- Oxygenate the wort. Yeast needs oxygen to multiply, which is the first thing they do before making alcohol. Our wort usually gets oxygenated by pouring it from a height from the boiler into the fermenter. So with this kit I was vigorous with the mixing of the malt extract and water.

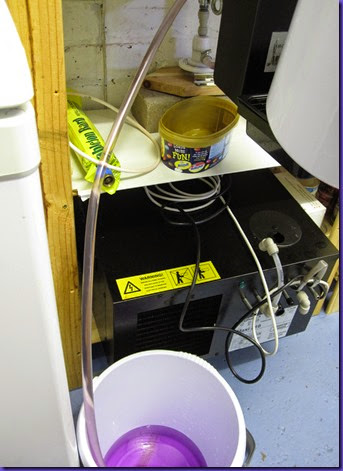

- Fermentation temperature. I am coming to the view that this is critical to the flavour you get in the finished beer. Warmer fermentations produce more fruity and fatter flavours. Cooler fermentations produce cleaner, less cluttered flavours. I like to ferment my ales at 18C, which is tricky because the house is 1-2C warmer than that. The garage is too cold (and the temperature fluctuates too much), so I use a fridge with a temperature controller to make sure the temperature is dead on.

I shall be interested to see how it comes out. Hopefully, served through my beer engine, it will be a nice clean bitter. We’ll see.

Meanwhile, the difference in the cost between all-grain and kit brewing interests me. This kit cost £24. That’s the total cost, apart from boiling the kettle a few times.

Here’s a rough breakdown of the cost of an all-grain batch:

- 5kg malt £7.50

- 50g hops £2.50

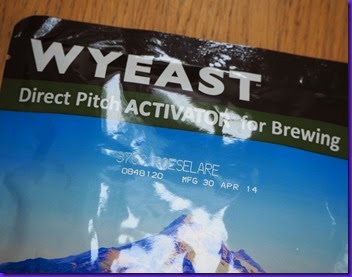

- Safale S-04 yeast £3

- Running the boiler (2kW for ~2 hours) 60p

- 12 man-hours (myself and Andy for six hours) Priceless

So that makes £13.60. I think St Peter’s and the retailer have some profit factored in there, even after the cost of packaging and distribution…