It’s been a long time since the last blog post because we’ve not done anything beery for a while (apart from drinking it!). But tonight we made some beer, so I thought it might be a good idea to bang out a blog post whilst the wort chills. (20:22, 68C).

Tonight’s Brew

It’s winter. It’s cold and dark and generally rubbish weather. At this time of the year you need dark rich winter-warmers. In order to appease me, and my liking for milds, Andy agreed that we’d make a beer based on Gale’s Festival Mild. But this is no ordinary mild: 1.058 (so probably about 6%), very black and hopefully very delicious.

Recent Tastings

Recently we’ve been drinking two brews: The Rye Experiment and Shutlingsloe.

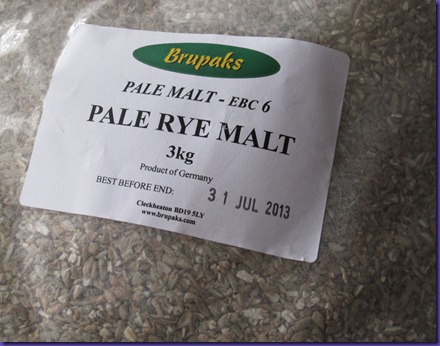

The Rye was certainly successful – not a bad bitter, but with something different about it that I can’t out my finger on. People say rye gives beer more of a “grainy” taste. I’m not exactly sure what that means, but I suspect that’s what we got!

However the Shutlingsloe was a real success. It’s a smooth, deeply dark and rich beer, but still a bitter. It’s not sweet; rather it’s strong, dark and bitter. Big success. That will be going into the Cheshire Peaks range for future re-brews.

Popping Hops

Our friend Andy Bowers has reported a strange phenomenon when he adds his wort chiller to his boiling wort. The hops seem to find their way into the spiral of the chiller, and push up above the level of the wort. We thought nothing more of it until today, when it happened to us too. No idea why. Answers on a postcard.

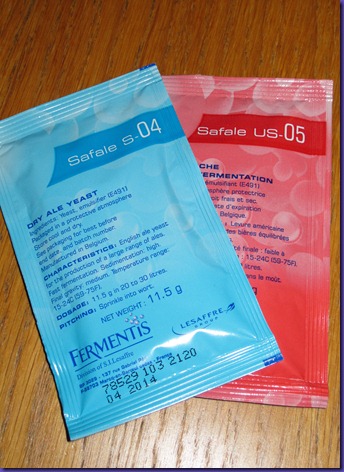

S-04 versus US-05

Considering we’ve not been brewing that long, our brewing preferences have already diverged from those of Andy Bowers. Regular readers will know that we recently undertook the Great British Brew Off, to see if our mashing techniques have a noticeable effect on the outcome of a beer. Results pending on that one.

Another of our diverged preferences is yeast. At Cheshire Peaks we’ve settled on Safale S-04 – a high quality dried English Ale yeast. We love it because the taste is good, but it’s also really reliable to use – it ferments well, gives average attenuation (ferments most but not all of the sugars, leaving a bit of sweetness) and, in particular, drops out to the bottom of the fermenter like a stone when it’s finished (called flocculating).

Andy Bowers on the other hand has primarily used Safale US-05 – a similar dried yeast, but with a very clean neutral flavour. He claims it’s far better.

I guess even if you haven’t been doing something for a long time you still tend to develop a preference for what you know.